QUALITY INDUSTRIAL X-RAY COMPANY PRIVATE LIMITED

QUALITY INDUSTRIAL X-RAY COMPANY PRIVATE LIMITED is Established in 1990, a leading Non-Destructive Testing (NDT) service provider based in India. With over three decades of industry expertise, we have built a strong reputation for delivering reliable, high-quality NDT solutions tailored to meet the needs of various industrial sectors.

Our team comprises specially qualified EN Level-II and ASNT Level-III certified professionals and a multi-disciplinary group of senior engineers who bring deep technical knowledge and hands-on experience to every project. We pride ourselves on our customer-centric approach, focusing on delivering precision, safety, and efficiency in all our services.

QUALITY INDUSTRIAL X-RAY COMPANY PRIVATE LIMITED is an ISO 9001:2015 certified organization committed to maintaining the highest standards of quality and compliance. Our processes and methodologies are aligned with international standards, ensuring consistent and accurate results for our clients.

Vision

"To be a trusted leader in Non-Destructive Testing by delivering innovative, reliable, safe and timely inspection solutions that uphold the highest standards of quality and integrity across industries."

Mission

“To safeguard industries and infrastructure through precision-driven Non-Destructive Testing solutions, delivered with integrity, innovation, and an unwavering commitment to excellence."

Quality Policy

Quality is not just a standard, it is our identity. "We are committed to delivering accurate, reliable, and world-class Non-Destructive Testing (NDT) services that meet or exceed customer expectations, comply with international standards, and contribute to the safety and integrity of critical infrastructure."

Why Choose Us!

- Legacy of Trust Since 1990

- Comprehensive NDT Solutions

- Cutting-Edge Technology

- Certified, Skilled Professionals

- Client-Focused, Solution-Driven

- Zero Compromise on Quality & Safety

- Fast Response, Reliable Service

- Most economical rates (value for money)

What We Are Bring On Board..

State-of-the-art NDT Testing Infrastructure in india

Experience

Satisfied Clients

Aerospace Quality System / Commercial NDT Testing

What we value most

TIMELY SERVICE

On time quality service is the motive of our firm. Hence we are having a huge team of skilled employees and multiple testing devices to provide services on committed timeline.

TOP QUALITY SERVICE

We are well know for our quality services and customer relationship. This is not just a statement to impress you but you will feel it once will be in direct contact with us. Quality is our Responsibility

INTEGRITY

We uphold transparency and honesty in all our actions. We are certified with LEVEL I and LEVEL II

Our Clients

Advance Inspection Services

Digital Imaging for Non-Destructive Testing Computed Radiography (CR) is an advanced non-destructive testing (NDT) technique that replaces traditional film radiography with digital imaging technology. It uses phosphor imaging plates to capture X-ray or gamma-ray exposure data, which is then processed using a laser scanner to create a high-resolution digital image. This digital image can be enhanced, analyzed, and stored electronically, offering a faster, more efficient, and environmentally friendly alternative to conventional radiographic methods.

Key Features

- High-resolution digital images for accurate defect evaluation

- No need for chemical film development

- Immediate image viewing and reporting

- Lower exposure times and reduced radiation dose

- Easy image storage, sharing, and archiving

Key Features:

- Weld inspection (pipelines, pressure vessels, structural steel)

- Casting flaw detection

- Aerospace component verification

- Corrosion and erosion analysis

- Quality control in manufacturing environments

Advanced Ultrasonic Imaging for High-Precision Inspection Phased Array Ultrasonic Testing (PAUT) is a sophisticated non-destructive testing (NDT) technique that uses multiple ultrasonic elements and electronic time delays to steer, focus, and scan beams of sound waves. This allows for detailed imaging of internal structures and detection of flaws with a high degree of accuracy. Unlike conventional ultrasonic testing, PAUT can generate multiple inspection angles and focal depths from a single probe, significantly improving coverage, speed, and data quality.

Key Features:

- Real-time cross-sectional imaging (sectorial and linear scans)

- Precise defect sizing and location

- High-speed scanning and data acquisition

- Customizable scan angles without mechanical probe movement

- Digital data storage and advanced reporting capabilities

Applications:

- Weld inspection in pipelines, pressure vessels, and structural components

- Corrosion mapping and thickness profiling

- Crack detection in complex geometries

- In-service inspection and maintenance in oil & gas, power, and aerospace industries

- Replacement for radiography in many code-compliant inspections

Advantages Over Traditional UT:

- Improved inspection accuracy and repeatability

- Greater coverage with fewer probe setups

- Enhanced data visualization with B-scan, C-scan, and S-scan displays

- No radiation hazard—safe for use in occupied areas

Phased Array Ultrasonic Testing is a powerful solution for high-resolution, reliable, and efficient ultrasonic inspection. It enhances defect detection while reducing inspection time and improving safety on-site

High-Precision On-Site Metal Analysis A Mobile Spectrometer using Optical Emission Spectroscopy (OES) is a highly reliable and accurate tool for on-site chemical analysis of metallic materials. OES technology is especially valuable in detecting light elements such as carbon (C), sulfur (S), phosphorus (P), and boron (B)—elements that are critical in determining alloy grades and material properties. This technique involves generating a controlled electric spark that excites atoms on the metal surface. These atoms emit light at specific wavelengths, which are then analyzed by the spectrometer to identify and quantify the elements present.

Key Features:

- Detection of light elements (e.g., C, P, S, B, N) not measurable by XRF

- Highly accurate elemental analysis of ferrous and non-ferrous metals

- Instant grade verification for stainless steels, low alloy steels, aluminum, copper, and nickel alloys

- Rugged and mobile design for use in harsh industrial environments

- On-board software for data logging, material certification, and reporting

Non-Destructive Evaluation Using Electromagnetic Induction Eddy Current Testing (ECT) is a widely used non-destructive testing (NDT) technique based on the principles of electromagnetic induction. It is primarily used for detecting surface and near-surface flaws in conductive materials, such as cracks, corrosion, inclusions, or changes in material properties. In ECT, an alternating current is passed through a coil to generate an oscillating magnetic field. When this coil is placed near the conductive material, it induces circulating eddy currents within the surface of the material. Disruptions in the flow of these eddy currents—caused by defects or material variations—are detected and analyzed to assess the integrity of the component.

Key Features:

- Surface and near-surface defect detection

- No need for couplant (dry testing method)

- Instant results with real-time signal analysis

- Highly sensitive to small cracks, especially in non-ferrous metals

- Can detect changes in hardness, conductivity, and heat treatment

Our Valuable clients

Services

Radiography Testing

Radiographic Testing (RT) is a non-destructive examination (NDE) technique that uses either X-rays or gamma rays to inspect the internal structure of a component without causing any damage. During testing, the test object is positioned between a radiation source and a film or digital detector. Variations in material thickness and density cause differential attenuation of the radiation as it passes through the component, due to absorption and scattering effects.These variations are captured as contrast differences, either on radiographic film or via digital imaging systems. RT is capable of revealing internal discontinuities such as cracks, voids, porosity, and inclusions.

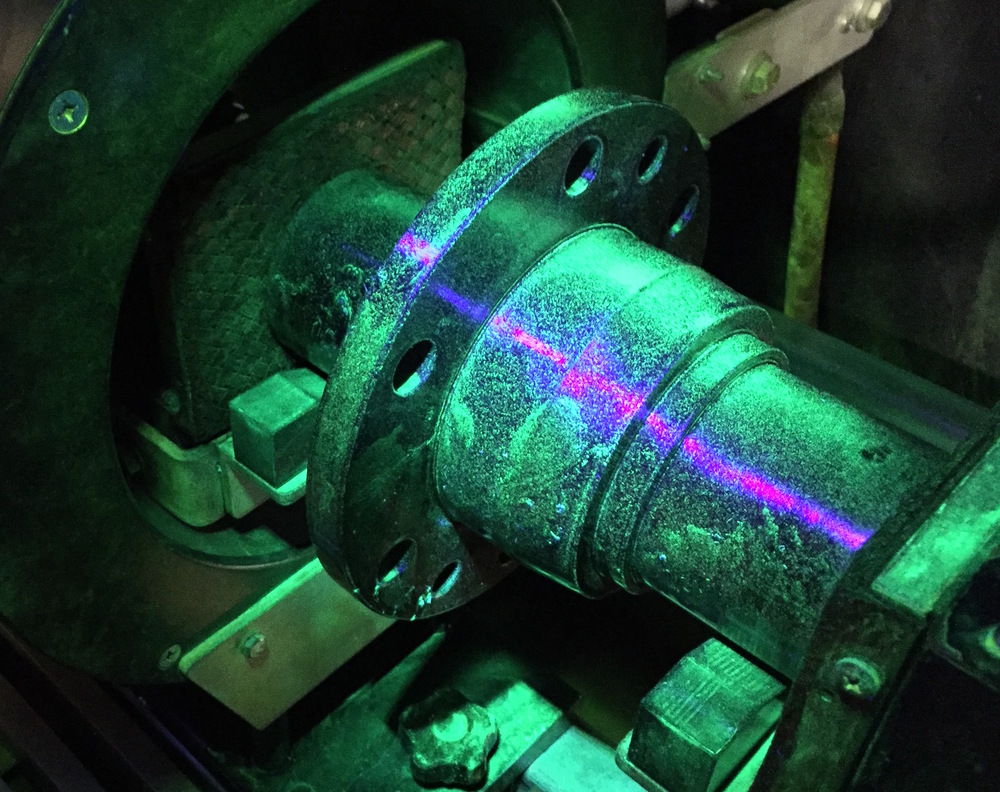

Magnetic Particle Testing

MPT is a non destructive testing method for locating surface and near surface discontinuities in ferromagnetic materials. It depends for its operation on the fact that when the material or part under test is magnetised, discontinuities that lie in a cause leakage field to the direction of the magnetic field will cause a leakage field to be formed at and above the surface of the part. The presence of this leakage field, and therefore the presence of the discontinuity, is detected by the use of finely divided ferromagnetic particle applied over the surface, some of the particle being gathered and held by the leakage field.

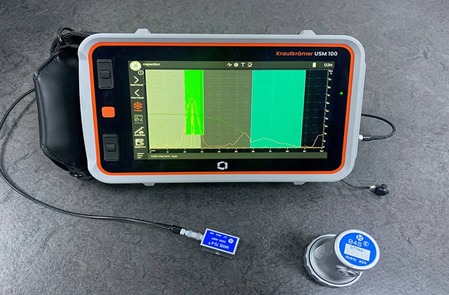

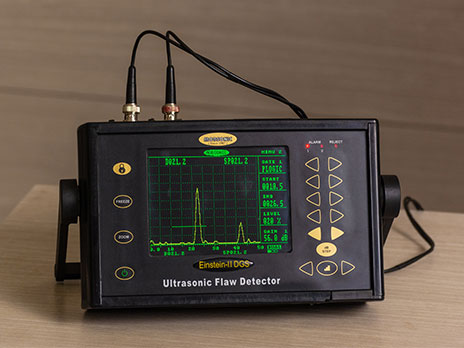

Ultrasonic Testing

UT is a non-destructive testing (NDT) technique that uses high-frequency sound waves to detect internal flaws such as cracks, voids, and other discontinuities in materials and components.The method involves transmitting a beam of ultrasonic energy into the test object. This sound wave, typically above the range of human hearing, travels through the material with minimal energy loss. However, when it encounters a discontinuity—such as a crack or void—the wave is partially reflected back to the transducer. These reflections are then analyzed to determine the location, size, and nature of the flaw.

Liquid Penetrant Testing

LPT is widely used to detect surface-breaking defects such as cracks, porosity, and voids in non-porous metallic materials. The selection of penetrant sensitivity level depends on the surface condition of the test material. For rough surfaces like castings, a lower sensitivity penetrant (Level 1/2) is typically used, while smoother, machined surfaces require higher sensitivity levels (such as Level III) to ensure accurate and reliable detection of fine defects.

Positive material identification

PMI using Handheld X-ray Fluorescence (XRF) is a fast, non-destructive testing technique used to verify the chemical composition of metallic alloys. This method is critical in quality control, material verification, and ensuring compliance with industry standards. The handheld XRF analyzer emits X-rays that interact with the atoms in the material, causing them to emit secondary (fluorescent) X-rays. These are then detected and analyzed to determine the elemental composition of the material

Hardness Testing

Portable Hardness Testing – Leeb & UCI Methods Portable hardness testing using Leeb and UCI (Ultrasonic Contact Impedance) methods provides a quick, non-destructive means of determining the hardness of metals and alloys directly on-site, without the need for laboratory equipment. Leeb Hardness Testing The Leeb rebound method measures the loss of energy of a test impact body after it strikes the material surface. The hardness value is calculated based on the ratio of the rebound velocity to the impact velocity. This method is especially suitable for testing large, heavy components such as forgings, castings, and heat-treated parts.

Certification & Membership

Managing Team

Parth Amrutiya

Managing DirectorASNT Level III , EN ISO 9712 Level II

Harsh Gandhi

Technical DirectorBARC Level II (RSO)

Contact

Our Address

3A Basement,Vimal Udhyog Bhavan,

M.N. Road,Matunga (W.R), Mumbai, India

Email Us

info@qualityndt.in

Call Us

+919769282854

+917600648888